URBANISTES LR

Blog Transports et Véhicules

-

Voiture Télécommandée Tout-Terrain : Avantages et Inconvénients

Dans le monde passionnant du modélisme, les voitures télécommandées tout-terrain se distinguent par leur polyvalence et leur capacité à affronter divers types de surfaces. Ces…

-

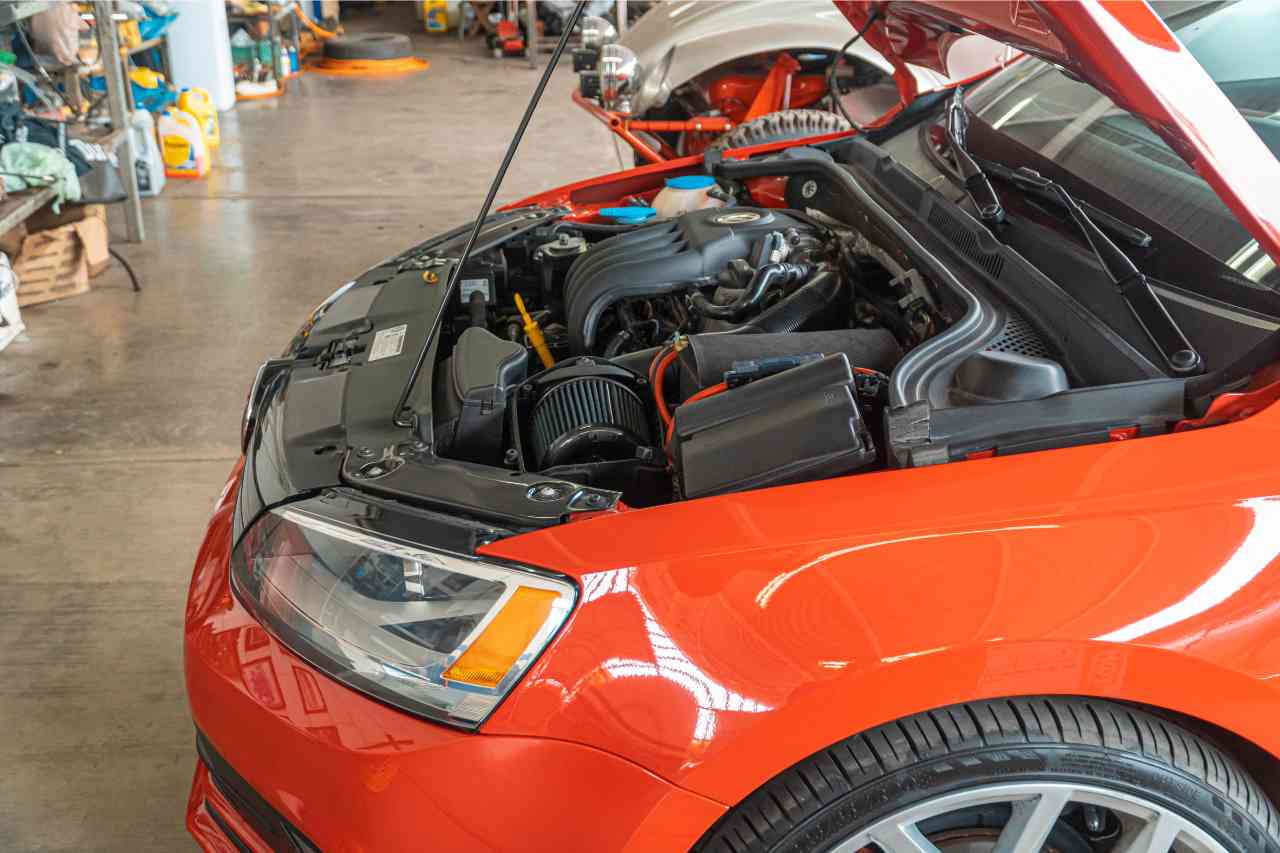

Casse auto à La Roche-sur-Yon : Guide complet

Découvrez tout ce que vous devez savoir sur les casses auto à La Roche-sur-Yon dans notre guide complet. Trouvez des conseils pratiques pour vendre ou…

-

Le Cendrier en Ville pour la Propreté et contre la Pollution

L’installation et l’utilisation de cendrier en ville s’avèrent essentielles pour la propreté et la lutte contre la pollution. Car l’un des problèmes les plus courants…

-

Les Cendriers Urbains contre la Pollution

L’utilisation de cendriers urbains est une solution efficace pour combattre le fléau de la pollution de l’environnement. Ce qui est un problème majeur qui affecte…

Je suis Raymond F. urbaniste passionnés de l’univers des transports en général et des véhicules en particulier.

Dans ce blog, je donne des informations et des idées pour mieux connaître les autos, motos, avion et bateau.